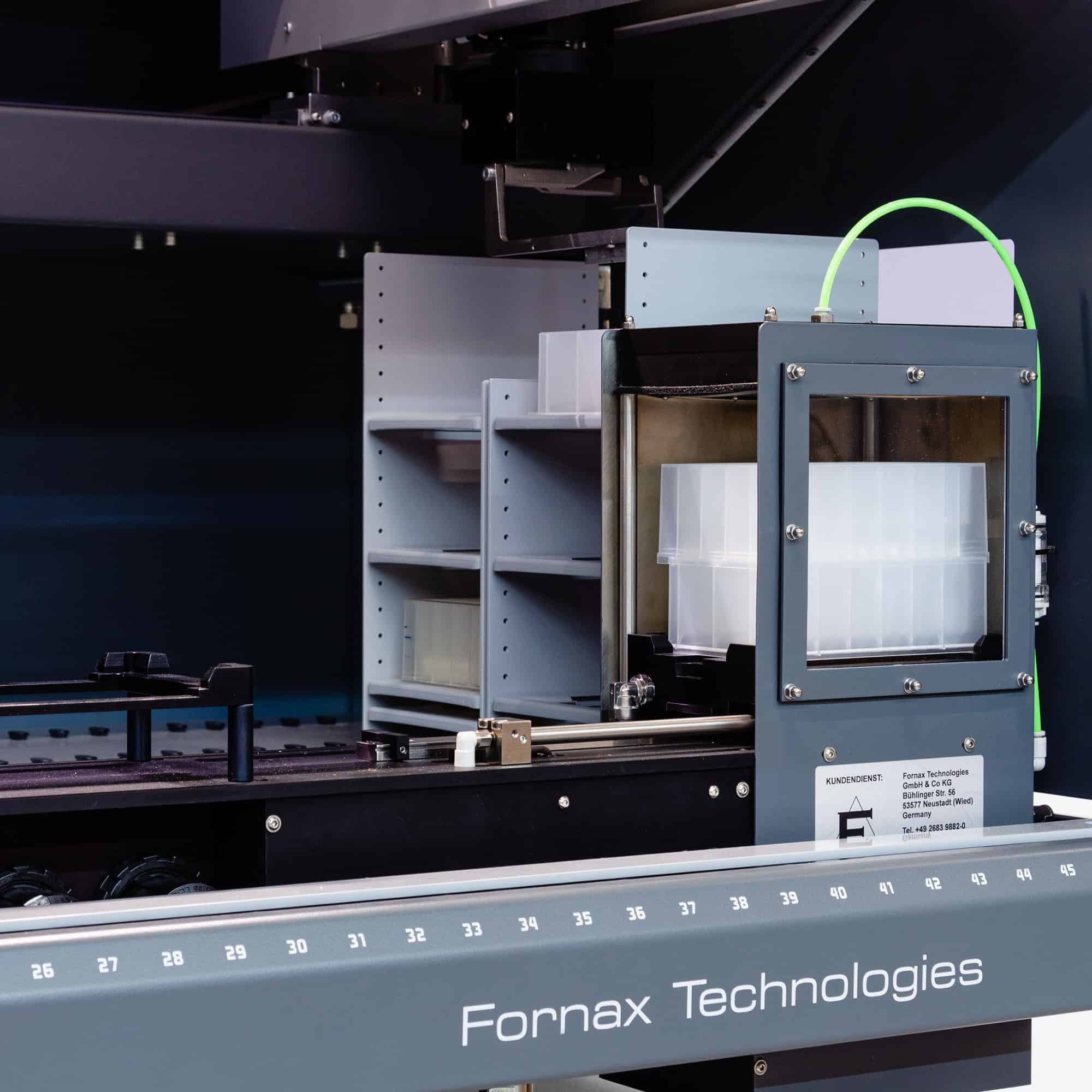

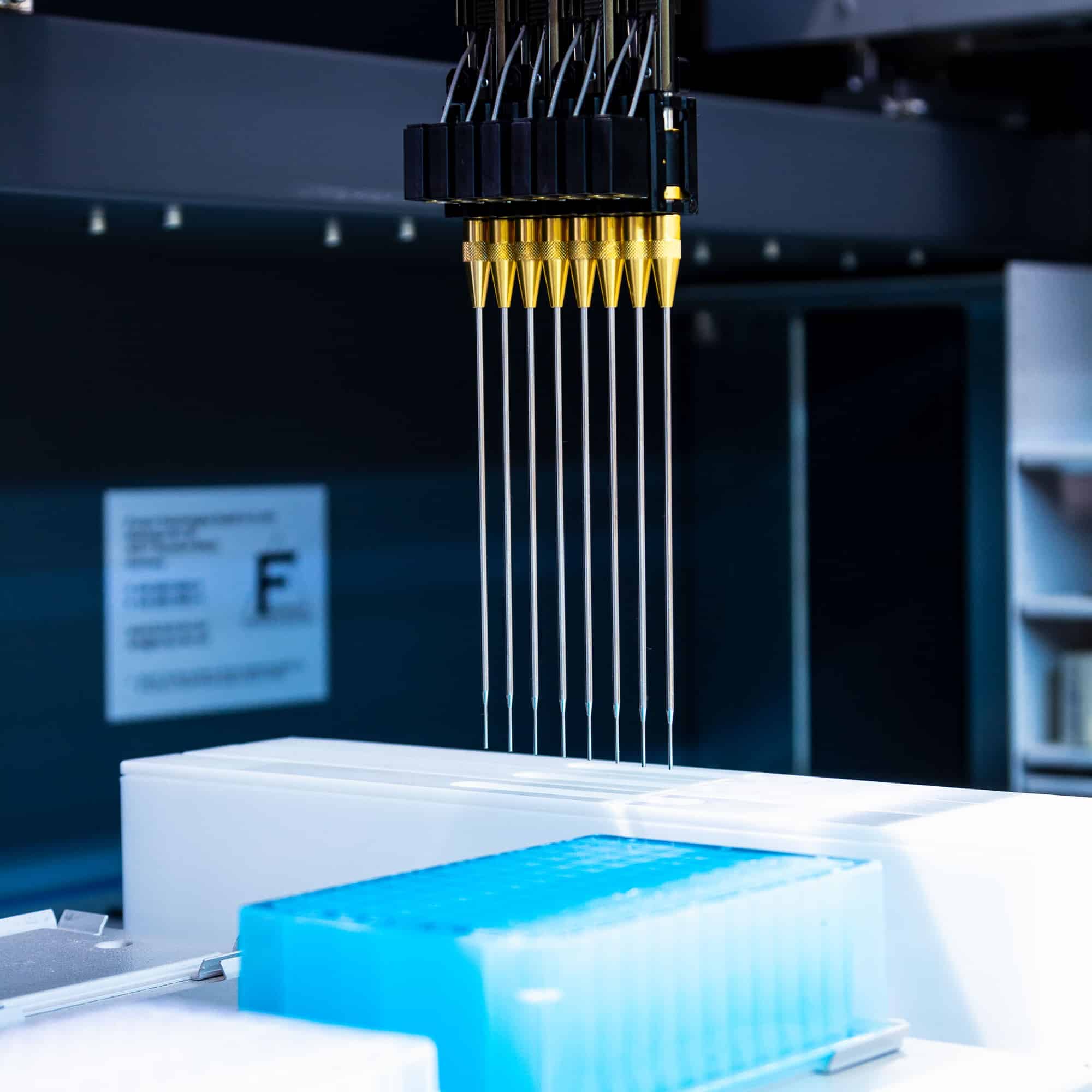

The FORNAX TECHNOLOGIES SPE workstation is based on a 96 well Positive Pressure Extractor (PPE), which is integrated in a Tecan Liquid Handler, for example for MS Smart Sample Preparation, and is controlled by a graphic user interface (GUI) that depicts the entire SPE process.

In line with our mission statement, we use reconditioned liquid handling robots to execute a fully automated, reliable and cost-effective SPE process.

The FORNAX TECHNOLOGIES SPE processor enables automatic purification, extraction and filtration on Tecan Freedom EVO platforms up to a pressure of approx. 7 bars for the following applications:

- Solid phase extraction (SPE) e.g. for DNA extraction

- Solid phase purification, for example with SOLA SPE cartridges/plates from Thermo Fisher Scientific

- Concentration of proteins/peptides and buffering, for example with Amicon Ultra or D-Tube from Millipore or Vivaspin from Sartorius without a centrifugation step

- Sterile filtration

- Flexible automated processing of 1 to 96 samples in parallel, for example individual columns 1, 3 or 6 ml or 96/384 filter plates

- Evaporation

The advantages of the FORNAX TECHNOLOGIES SPE workstation compared with the use of a vacuum or centrifugation are primarily:

- Simple refitting of the liquid handling robot from the Tecan EVO 100, 150 and 200 series.

- The pressure remains constant even if only one well in the filter plate or one filter cartridge is still full.

- The constant pressure guaranteed for each position in the filter plate or adapter plate ensures a high reproducibility of the extraction/filtration.

- The pressure of up to approximately 7 bars is 6 times higher than in a vacuum.

- Increase in the throughput for the automated extraction/filtration.

- No need to mask the filter plate when there is limited use of the labware.

- The processor automatically adjusts to different heights of the labware.

- Different adapters enable the use of filter plates (e.g. 96 or 384 filter plates) or different sized filter cartridges.

- The pressure can be electronically controlled during the application to ensure high flexibility for the extraction/filtration steps.