We can individually adapt your Tecan system and use our expert knowledge to help you in all areas of lab automation.

Our spectrum covers test kit programming, drawing up and programming your application and constructing specific sample holders and bases. It also covers programming graphical user interfaces (GUIs) through to the complete development and construction of comprehensive, fully-automated applications, including the integration of various devices from numerous third-party providers.

We also implement clean room applications up to security level S2 together with you and our partners.

Customer-specific application development

Our spectrum of services for your special applications in the field of lab automation also includes creating graphic user interfaces (GUIs) and programming and creating scripts. For example, in Freedom EVOware and Freedom EVOware Plus. Furthermore, we offer the integration of hardware and software from third-party equipment into Tecan Freedom EVO systems, also as part of an application development with upstream clarification of feasibility.

Factory Acceptance Tests (FAT), Installation Acceptance Tests (IAT), site acceptance and comprehensive documentation naturally form part of all automation projects implemented by FORNAX TECHNOLOGIES.

Finally, we offer transfer of the individual expertise and comprehensive training on the customer’s own system as required.

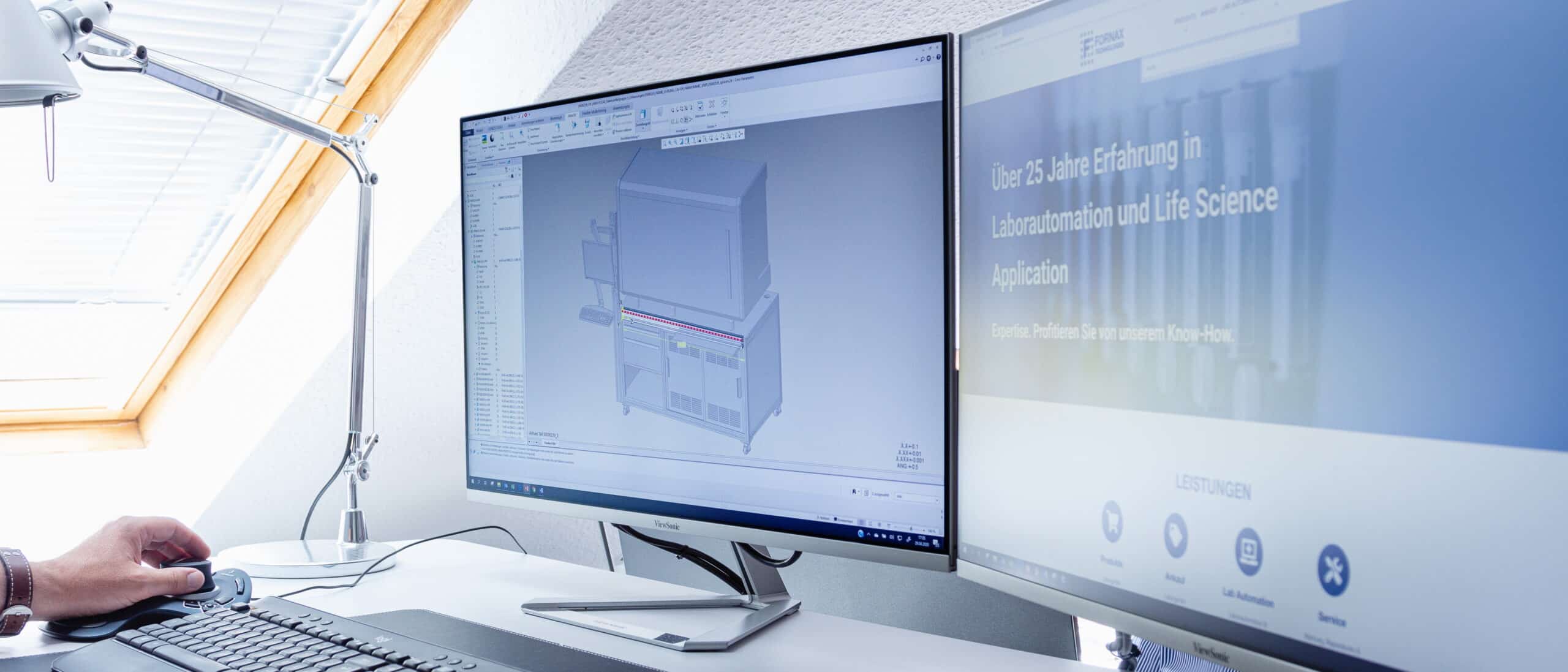

Individual constructions

FORNAX TECHNOLOGIES works together with selected partners to develop, construct and manufacture compatible accessories (e.g. for Hamilton or Tecan liquid handling robots) to individually adapt your system.

It goes without saying that we use the latest CAD software to create construction sketches. It is also the basis for producing with the high level of precision required for automated liquid handling systems.

Furthermore, we offer individually constructed solutions for modifications, extensions or special solutions for your specific lab automation applications. For example:

- Rolling and support tables

- Clean room solutions

- Refrigeration and low temperature cells for the temperature range -110°C to +4°C

- Customer-specific sample holders

- Special worktable adapter plates

- Integration of different devices from third-party providers

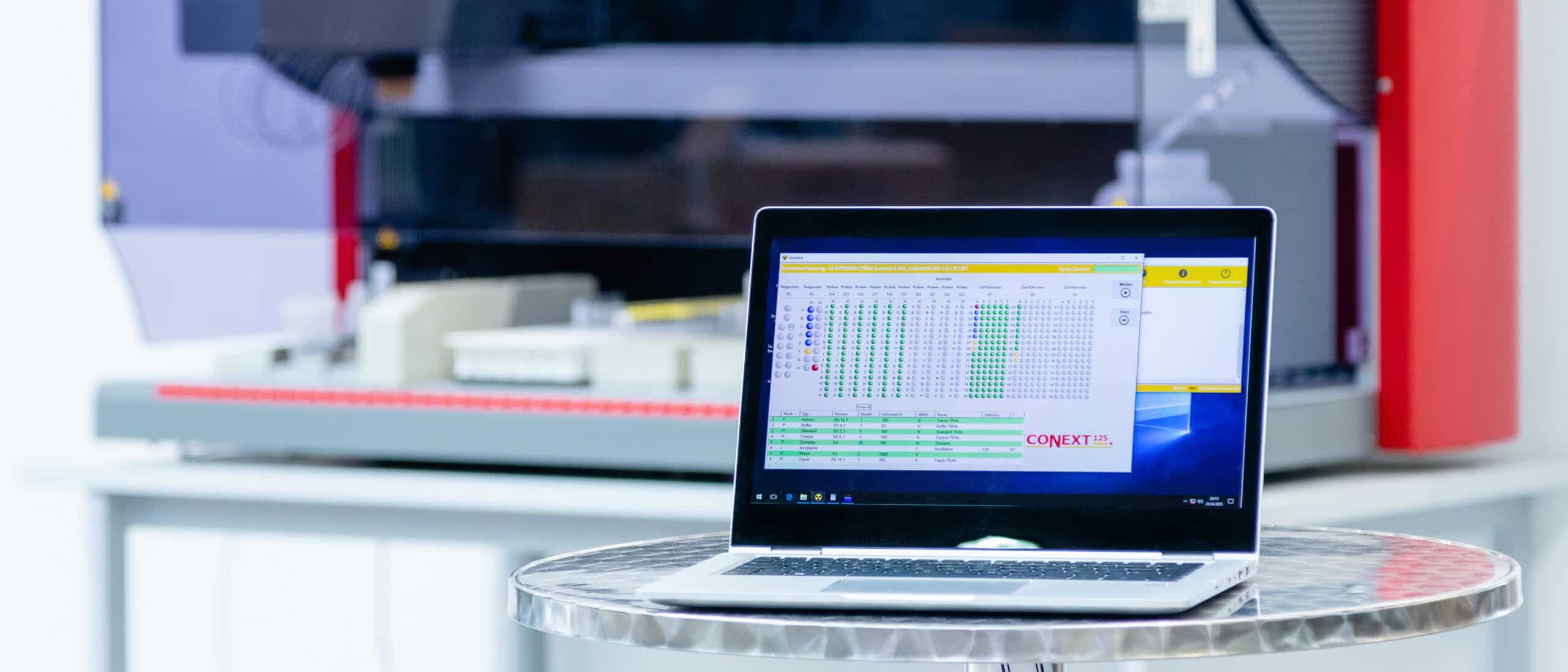

Radioimmunoassay (RIA)

The FORNAX TECHNOLOGIES RIA workstation (CONEXT 125) is a flexible, automatic, open sample distribution and washing system for radioimmunoassays on Tecan Genesis platforms.

Functionality of the RIA workstation:

- Automatic 4+4 channel pipetting and washing unit enables fast handling of patient samples.

- The system processes up to 96 samples in one cycle in a batch-oriented manner.

- It distributes sample material in one operation on up to 3 target racks each containing 96 test tubes. Different workflows can therefore be ideally combined.

- Within the corresponding workflow, the system distributes the necessary controls and standards for the evaluation in the gamma counter.

- At the end of the incubation period, the 4+4 channel washes the samples and, as required, changes between the test-specific washing solutions.

Solid Phase Extraction (SPE)

The FORNAX TECHNOLOGIES SPE processor enables automatic purification, extraction, filtration and evaporation on Tecan EVO platforms up to a pressure of approximately 7 bars. The SPE processor is therefore suitable for the following applications:

- Solid phase extraction (SPE) e.g. for DNA extraction

- Solid phase purification e.g. with SOLA SPE cartridges/plates from Thermo Fisher Scientific

- Concentration of proteins/peptides and buffering e.g. with Amicon Ultra or D-Tube from Millipore or Vivaspin from Sartorius without a centrifugation step

- Sterile filtration

- Flexible automated processing of 1 to 96 samples in parallel e.g. individual columns 1, 3 or 6 ml or 96/384 filter plates

- Evaporation

Advantages compared with vacuum or centrifugation for the SPE

- Simple refitting of the liquid handling robot from the Tecan EVO 100, 150 and 200 series.

- The pressure remains constant even if only one well in the filter plate or one filter cartridge is still full.

- The constant pressure guaranteed for each position in the filter plate or adapter plate ensures a high reproducibility of the extraction/filtration.

- The pressure of up to approximately 7 bars is 6 times higher than in a vacuum.

- Increase in the throughput for the automated extraction/filtration.

- No need to mask the filter plate when there is limited use of the labware.

- The processor automatically adjusts to different heights of the labware.

- Different adapters enable the use of filter plates (e.g. 96 or 384 filter plates) or different sized filter cartridges.

- The pressure can be electronically controlled during the application to ensure high flexibility for the extraction/filtration steps.

More about this topic? Further details can be found in our article from the trade journal transkript (issue 3.2019) on the subject of laboratory world automation in this PDF file: Transcript “Time for change” (PDF) [EN]